“Fit and Forget” for permanent peace of mind

NORMAQUICK® - Quick Connectors

Innovative, secure, and “quickfit” - the NORMAQUICK® range of plug-

in connectors made of synthetic material are suitable for most media

carrying lines. No matter whether we are dealing with cooling water,

oil, air or fuel carrying lines - NORMAQUICK® quick connectors offer

the state-of-the art means of connection. These connectors are speci-

ally suited to being matched up with the NORMAFLEX® tube system.

Speed

117

NORMAQUICK® - Quick Connectors

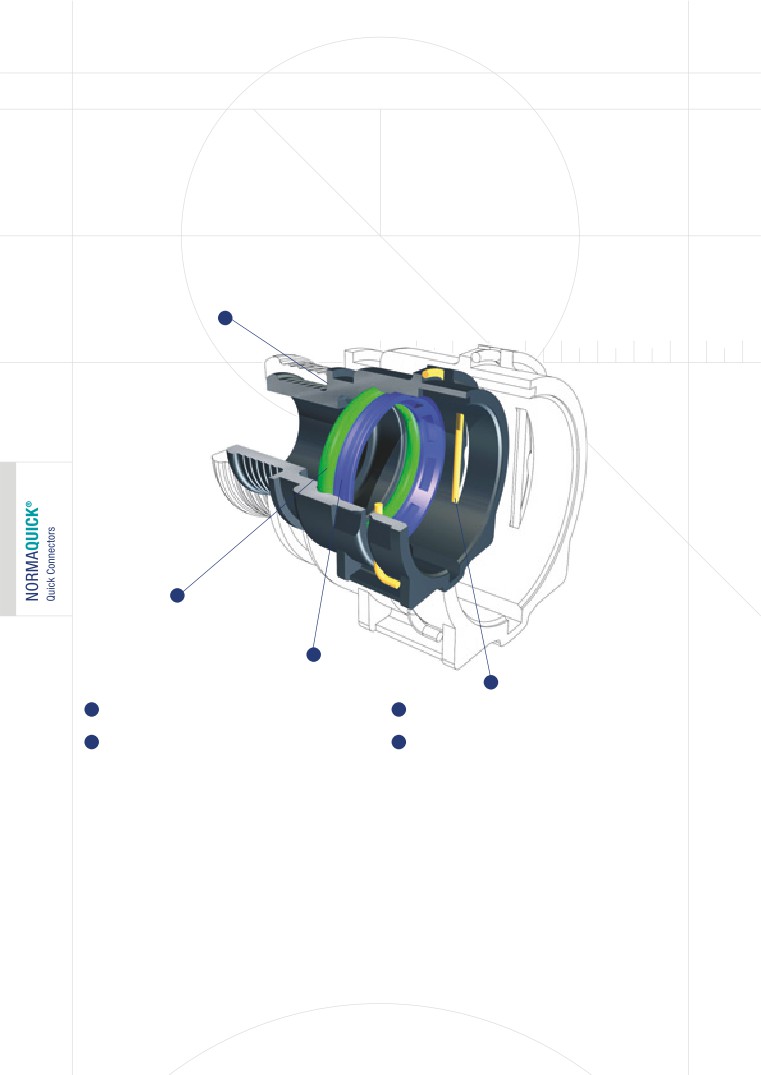

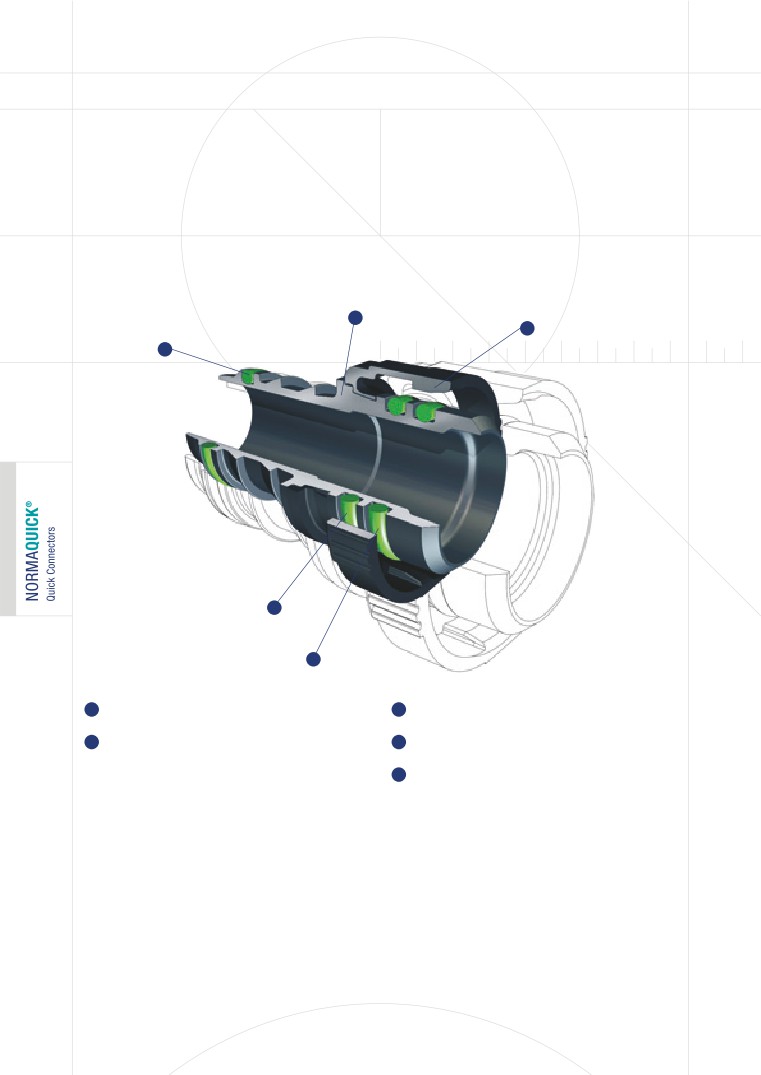

NORMAQUICK® PS3

NORMAQUICK® PS3 “Push & Seal” plastic quick connectors

Quick Connectors

are an ideal means for the secure connection of cooling water

and heating hoses as well as charged

air systems.

Short description of technical features

1

2

3

4

1

Spigot

3

Retaining ring

2

O-ring

4

Retainer (spring)

Standard materials

NORMAQUICK® PS3 quick connectors are made from recycla-

In case of special applications (e.g. charged air ducts) NORMA-

ble materials. For our standard versions we use Polyamide 6.6

QUICK® PS3 connectors can be made from other technical

with 30% glass fiber content.

thermoplastic materials with different filler types and contents.

Please note, however that special types can only be made

The standard material for the O-rings consists of peroxide-

when the required minimum quantity is ordered.

cured EPDM which is resistant to hot water. For NORMAQUICK®

PS3 connectors that are likely to be used in direct contact with

coolants we recommend PA 6.6 with 30% glass fiber content

that has been stabilized against heat and hydrolysis.

118

NORMAQUICK® - Quick Connectors

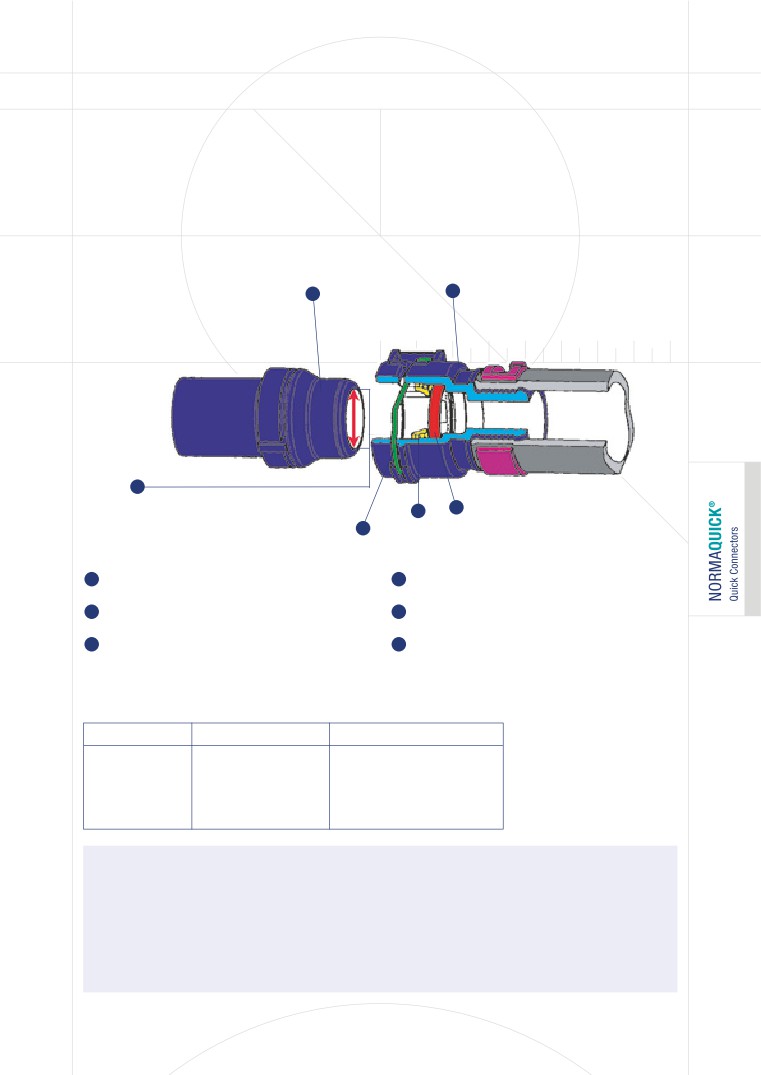

VDA-Connection spigot

Please note that all NORMAQUICK® PS3 connectors are deliver-

ed without spigot.

Spigot to VDA standard

But we will be pleased to offer suitable spigots on request.

1

6

2

5

4

3

1

Connection spigot

4

Retaining ring

2

Diameter of bore = Nominal Width (NW)

5

O-ring

3

Retainer (spring)

6

Connector

Technical features

Medium/Fluid

Operating Pressure

Operating Temperature

Cooling water

Approx. 1.5 bar

Engine compartment:

excess pressure

-40 °C to +135 °C

Short time up to +150 °C

(approx. 30 min.)

The advantages at a glance

• Snap assembly without tool = time and cost reduction

• Robot assembly possible = automated processes

• Compact structural dimensions = to be used in extremely narrow spaces

• Integrated seal = optimal tightness

119

NORMAQUICK® - Quick Connectors

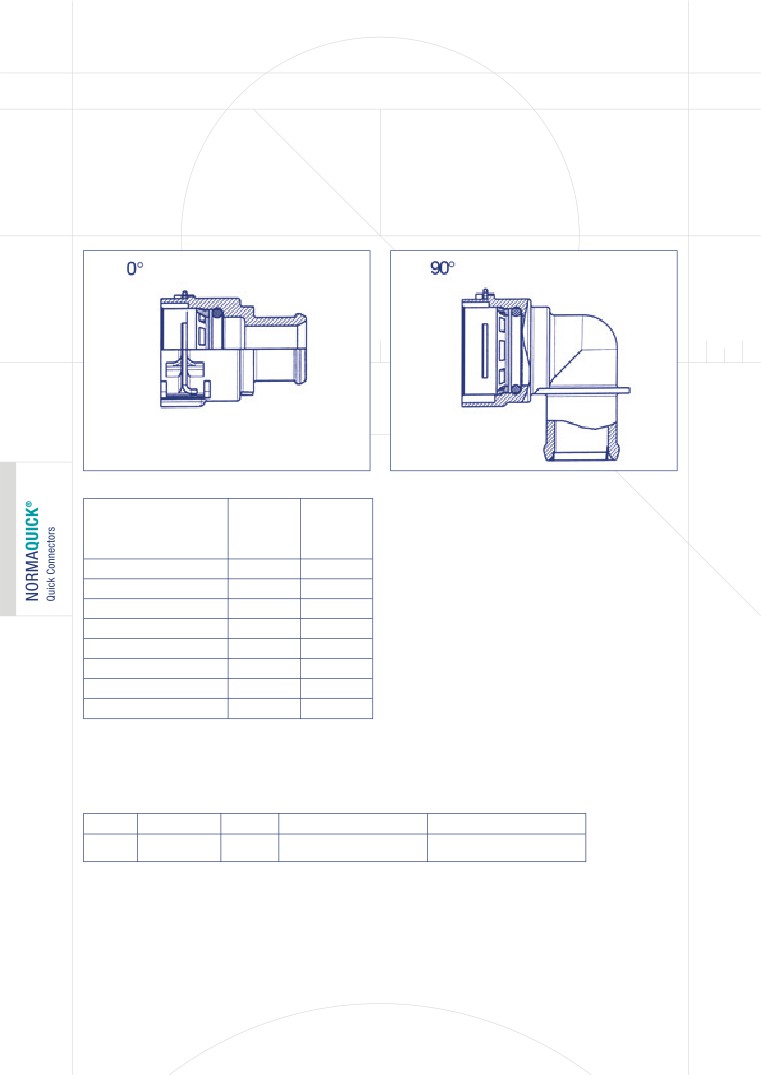

Survey of sizes

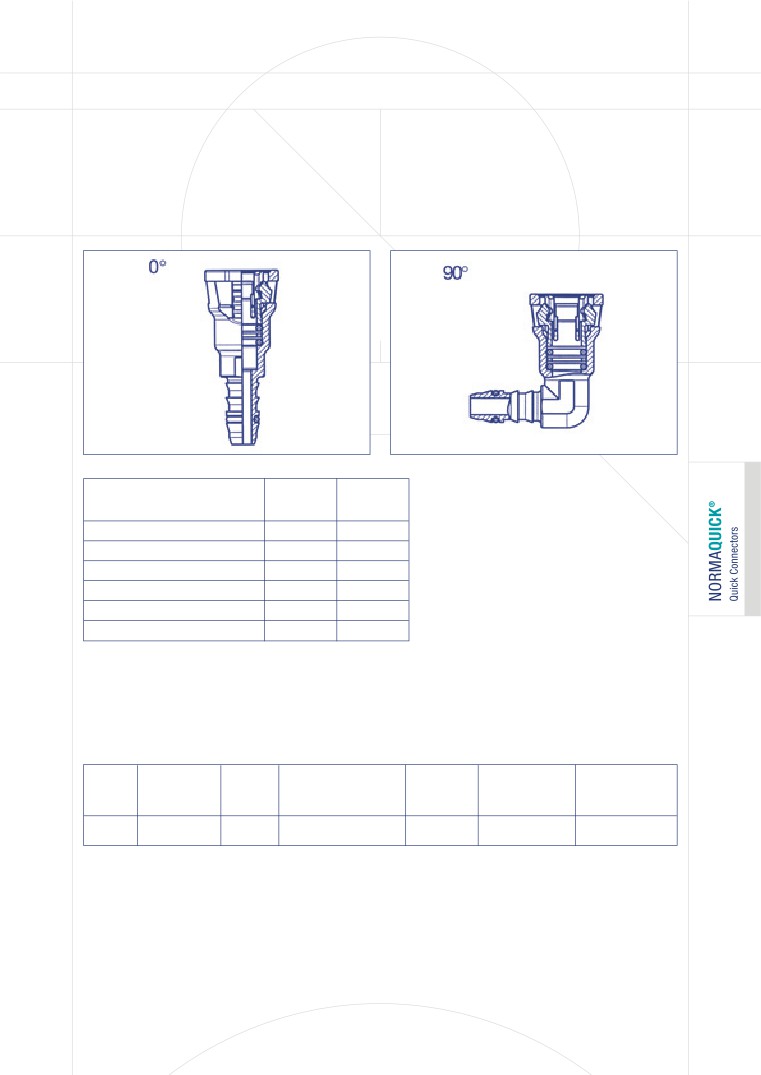

NORMAQUICK® PS 3

Two types of NORMAQUICK® PS3 (0° and 90°) are available as

standard versions.

Nominal diameters in mm

0°

90 °

(inside diameter

of the bore)

8

X

-

12

X

X

16

X

X

20

X

X

26

X

-

32

X

X

40

X

-

50

X

-

Enquiries/ordering:

When making enquiries or placing orders please state as follows:

1. Type

2. Nominal width

3. Variant

Example

NORMAQUICK

PS3

16

0°

During the last couple of years we have built up a selection of

special/customised connector types. The geometries can be

substantially modified to customer requirements and it is possi-

ble to integrate additional functional elements, e. g. thermo

sensors. We would be pleased to answer your questions.

120

NORMAQUICK® - Quick Connectors

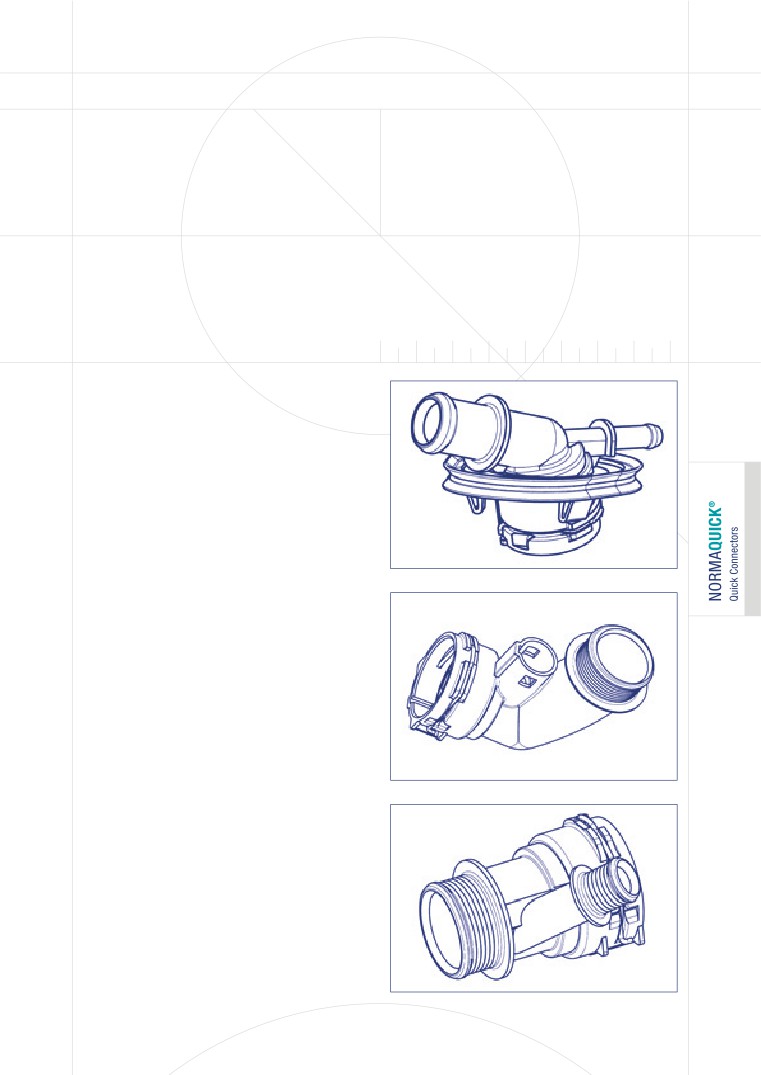

Applications

• Cooling water lines

• Heating lines

• Charged air connections

The following drawings show three practical examples:

NORMAQUICK® PS3 with integrated junction piece, seal and

branch

Flow-optimised NORMAQUICK® PS3 with integrated recep-

tacle for thermo sensor

NORMAQUICK® PS3 with integrated junction piece

121

NORMAQUICK® - Quick Connectors

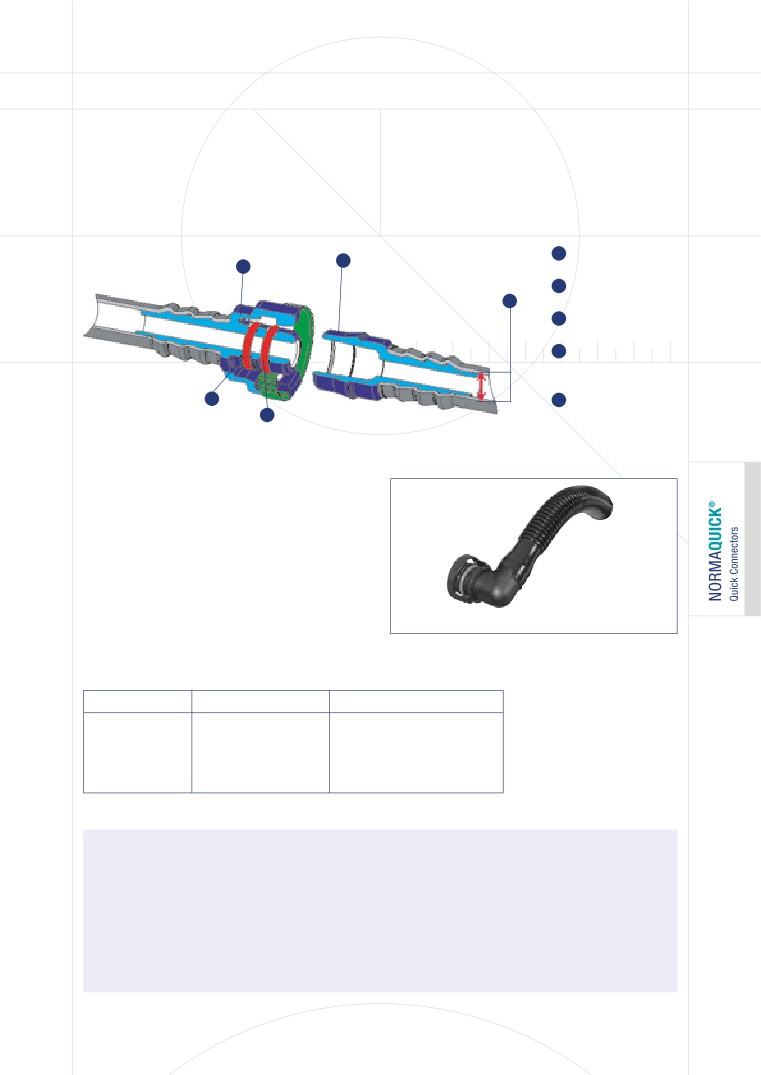

NORMAQUICK® V2

NORMAQUICK® V2 plastic quick connectors are an ideal means

Quick Connectors

to connect media carrying lines as

well as ventilation and

exhaust lines in the automotive industry.

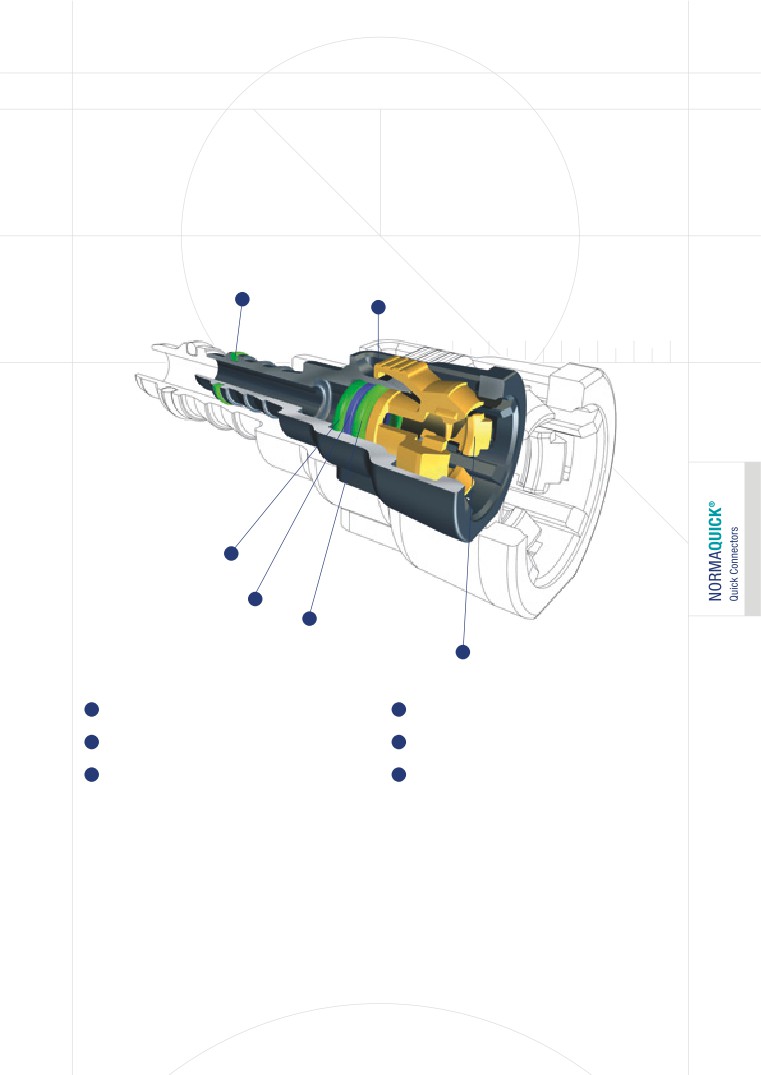

Short description of technical features

5

4

1

2

3

1

Firtree plus O-ring (optional)

3

Primary O-ring

2

Secondary O-ring

4

Locking device (ring)

5

Spigot

Standard materials

NORMAQUICK® V2 connectors are made from recyclable mate-

rials featuring extremely low permeation values. Our standard

versions are made from Polyamide 6 with 30 % glass fiber con-

tent or Polyamide 12 with 20 % glass fiber content. The O-rings

are made of NBR, HNBR, FPM and FVMQ as standard equip-

ment.

122

NORMAQUICK® - Quick Connectors

Connecting spigot

To RASMUSSEN standard (Production drawings will be made

Would you please note that all NORMAQUICK® V2 connectors

available on request)

NORMAQUICK® V2 connectors can be

are delivered without spigot. However,

we will be pleased to

used on both plastic and metal spigots.

offer suitable spigots on request.

1

Connector

5

1

2

Secondary O-ring

4

3

Primary O-ring

4

Pipe inside diameter

= Nominal Width (NW)

2

5

Spigot

3

Insiders’ Tip:

The perfectly matched system is achieved when combining

NORMAQUICK® V2 quick connectors and NORMAFLEX® fluid

systems.

Technical features

Medium/Fluid

Operating Pressure

Operating Temperature

Fuels, air, oil &

Approx. 5 bar

Engine compartment:

oil vapours

excess pressure

-40 °C up to +135 °C

Short time up to +150 °C

(approx. 30 min.)

The advantages at a glance

• Fast assembly without tool = reduced time and cost

• Robot assembly possible = automated processes

• Compact dimensions = to be used in narrow spaces

• Integrated seal = optimal tightness

• The seals can be visually checked = safe assembly work

123

NORMAQUICK® - Quick Connectors

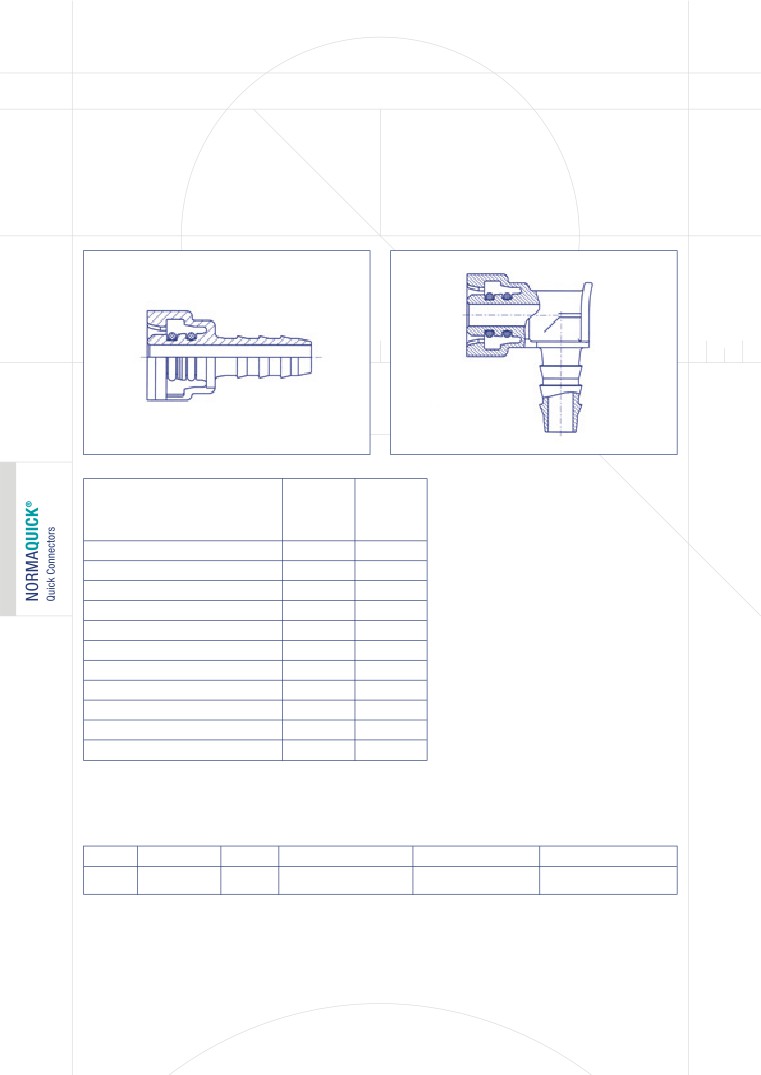

Survey of sizes

NORMAQUICK® V2

Two types of NORMAQUICK® V2 connectors (0° and 90°) are

available as standard versions.

0°

90 °

Nominal width (mm)

(inside diameter of the PA pipe

0°

90 °

to be connected)

4

X

X

6

X

X

7

X

X

8

X

X

10

X

X

12

X

X

15

X

X

19

X

X

25

X

-

27

X

X

33

X

-

Enquiries/ordering:

When making enquiries or placing orders please state as follows:

1. Type

2. Nominal width

3. Type

4. Application

Example

NORMAQUICK

V2

10

90 °

fuel

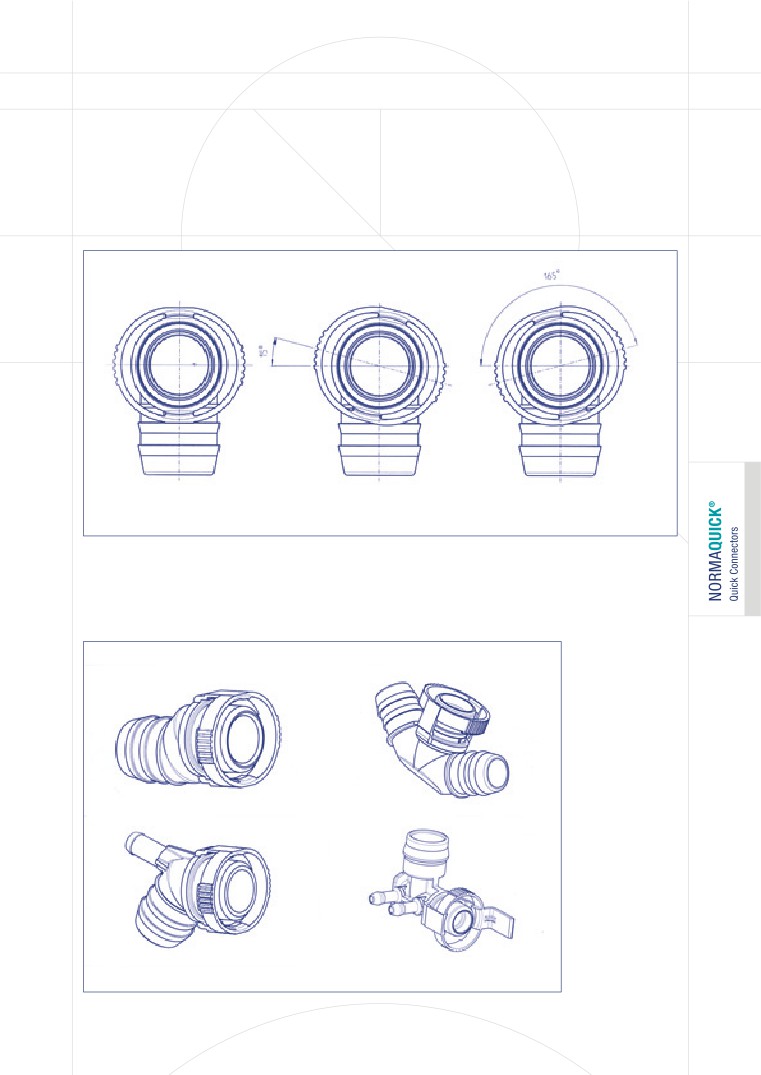

Special installation dimensions may require the dismantling ring

NORMAQUICK® V2-NW 19 with dismantling ring oriented at an

to be oriented at an angle which deviates from that of the stand-

angle of 15°, 30°, 45° etc. in steps of 15°

ard version. For such cases we supply quick connectors with

dismantling rings oriented at the following angles:

NORMAQUICK® V2-NW 27 with dismantling ring oriented at an

angle of 10°, 20°, 30° etc. in steps of 10°

124

NORMAQUICK® - Quick Connectors

The drawings show the principle as exemplified by the

NORMAQUICK® V2 NW 19, 90° quick connector:

0°-Position

15°-Position

165°-Position

(Standard position)

During the last couple of years we have built up a selection of

approx. 200 special/customised connector types. We will be

pleased to inform you in more detail on request.

Customised types

125

NORMAQUICK® - Quick Connectors

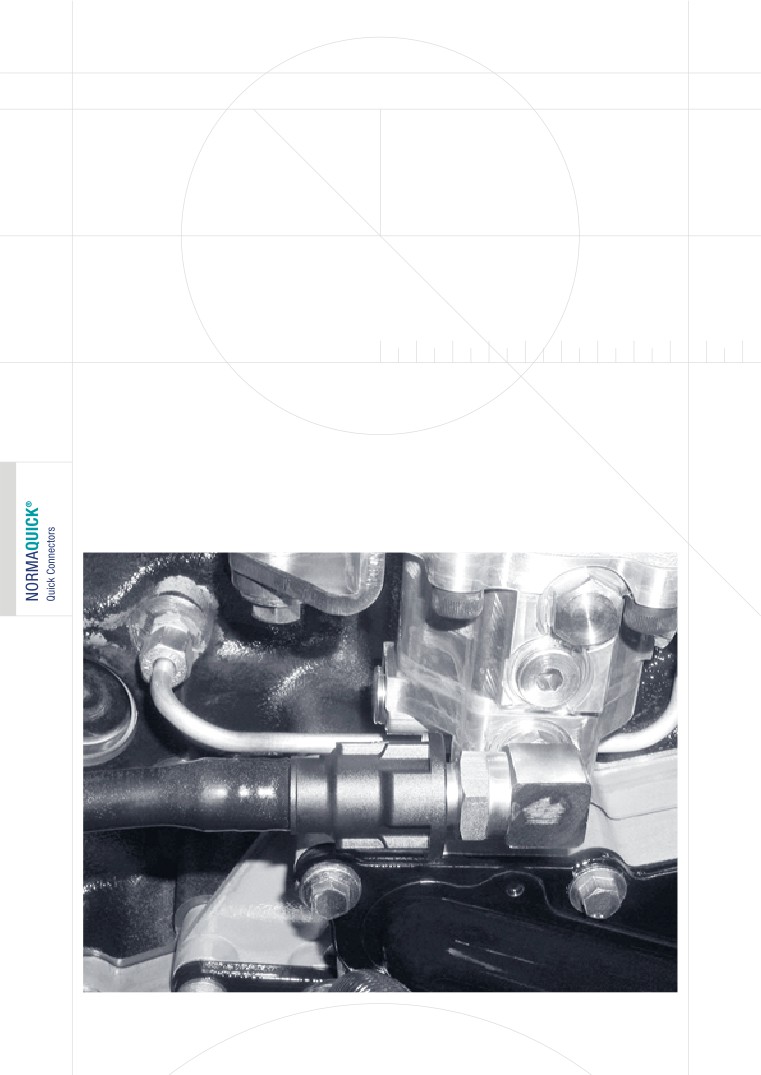

Applications

NORMAQUICK® V2 can be used for both line-to-line as well as

line-to-device connections.

• Fuel lines

- Tank breathing

• Ventilation and exhaust lines

- Secondary air lines

- Crank case ventilation lines

• Oil cooler lines

• Vacuum brake lines

126

NORMAQUICK® - Quick Connectors

NORMAQUICK® S

NORMAQUICK® S plastic quick connectors are an ideal means

Quick Connectors

to connect media carrying lines on

automobiles and have

basically been developed for fuel system applications.

Short description of technical features

1

6

2

3

4

5

1

Firtree plus O-ring (optional)

4

Secondary O-ring

2

Primay O-ring

5

Retainer (spring)

3

Spacer

6

Spigot

Standard materials

NORMAQUICK® S connectors are made from recyclable mate-

12 with 20 - 50 % glass fiber content. The O-rings are made of

rials featuring extremely low permeation values.

FPM and FVMQ as standard equipment.

Our standard versions are made from Polyamide 6 or Polyamide

127

NORMAQUICK® - Quick Connectors

Connecting spigot

to SAE J2044, standard world wide

Please note that all NORMAQUICK® S connectors are delivered

However, we will be pleased to offer suitable SAE spigots on

without SAE spigot.

request.

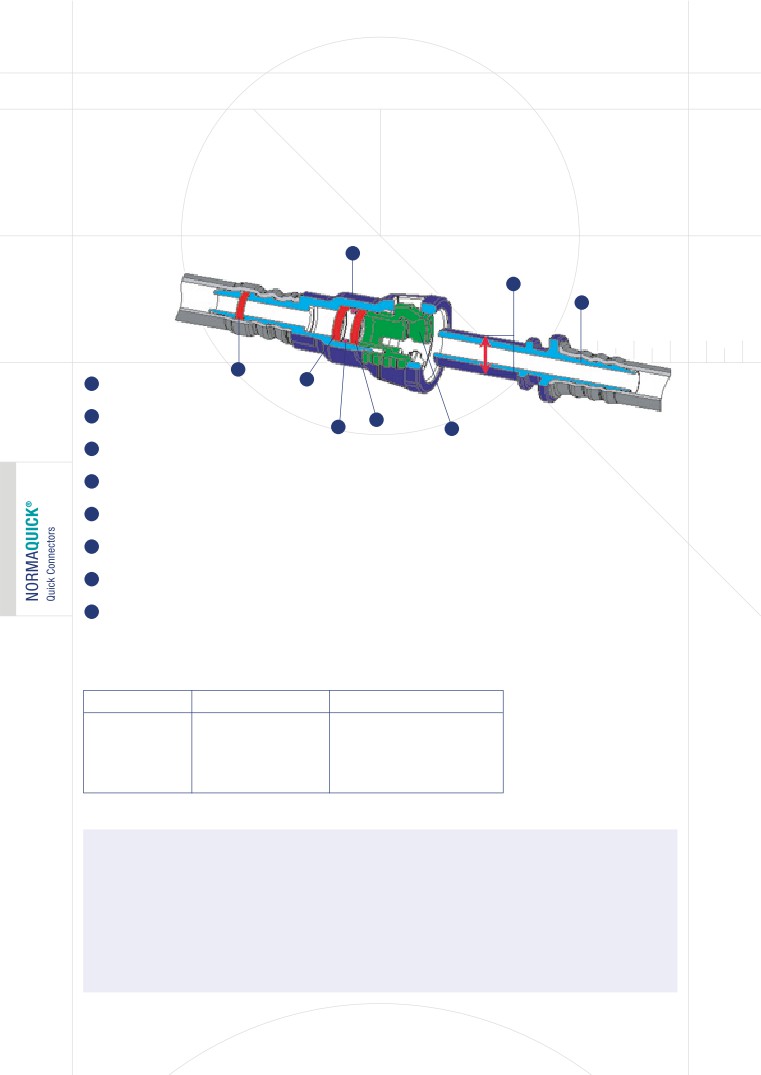

1

8

7

2

3

1

Spigot

2

Firtree plus O-ring (optional)

5

4

6

3

Primary O-ring

4

Spacer

5

Secondary O-ring

6

Retainer (spring)

Insiders’ Tip

7

Adapter

The perfectly matched system is achieved when combining

NORMAQUICK® S quick connectors and NORMAFLEX® fluid

8

Diameter of Connecting spigot = Nominal Width (NW)

systems.

Technical features

Medium/Fluid

Operating Pressure

Operating Temperature

Fuel

Approx. 10 bar

Engine compartment

excess pressure

-40 °C up to +135 °C

Short time up to +150 °C

(approx. 30 min.)

Meeting the requirements of SAE J2044

The advantages at a glance

• Fast assembly without tool = time and cost reduction

• Robot assembly possible = automated processes

• Compact building method = employment in extremely close installation conditions possible

• Integrated seal = optimal tightness

• Closing cone principle = NORMAQUICK® S is protected from unintentional opening and cannot be unlocked under pressure

128

NORMAQUICK® - Quick Connectors

Survey of sizes

NORMAQUICK® S

Two types of NORMAQUICK® S (0° and 90°) are available as

standard versions.

Nominal width (mm)

0°

90 °

(outside diameter of the spigot)

1/4”

X

X

5/16”

X

X

8 mm

X

X

3/8”

X

X

1/2”

X

X

5/8”

X

X

Additional nominal widths on request.

Enquiries/ordering:

When making enquiries or placing orders please state as follows:

1. Type

2. Nominal width

3. Type

4. Application

5. Inside line-

(outside diameter of

diameter

SAE spigot)

Example

NORMAQUICK

S

5/16“

0°

fuel

6 mm

Applications

NORMAQUICK® S can be used to make both line-to-line as well

as line-to-equipment connections.

• Fuel lines

• Ventilation lines

- feed and return lines

• Oil cooler lines

– tank breathing

• Vacuum control lines

129

NORMAQUICK® - Quick Connectors

NORMAQUICK® MK

and the pipe system in cases where existing standard con-

Connecting spigot

nectors are prone to a high permeation rate while their ten-

dency to “creep” causes additional micro leakage.

NORMAQUICK®

MK connectors have been developed with the

NORMAQUICK® MK for the first time combine reinforced and

aim to achieve significantly reduced permeation rates.

unreinforced materials and thus enable the safe connection

NORMAQUICK®

MK provide a perfect link between the tank

of the connector with the plastic fuel tank.

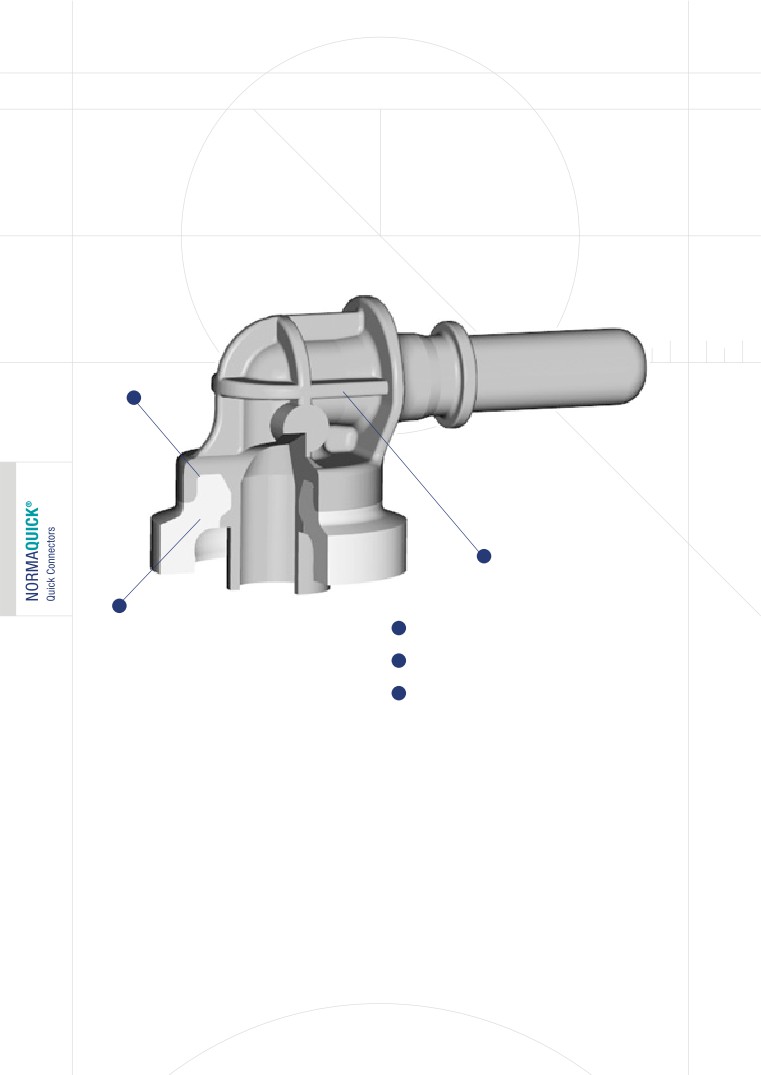

Short description of technical features

1

3

2

1

Chemical bonding

2

Welded ring HDPE

3

Spigot PA 12 (glass fiber reinforced)

Materials

NORMAQUICK® MK combine materials that so far have been in-

compatible. Welded ring made from HDPE, can be welded onto

the plastic fuel tank. Spigot made from Polyamide 12 with 30 %

glass fiber content.

130

NORMAQUICK® - Quick Connectors

Connecting spigot

NORMAQUICK® MK are applicable for

use with the following

connectors:

• SAE (e.g. NORMAQUICK® S)

• VDA (e.g. NORMAQUICK® PS 3)

• NORMAQUICK®

V2

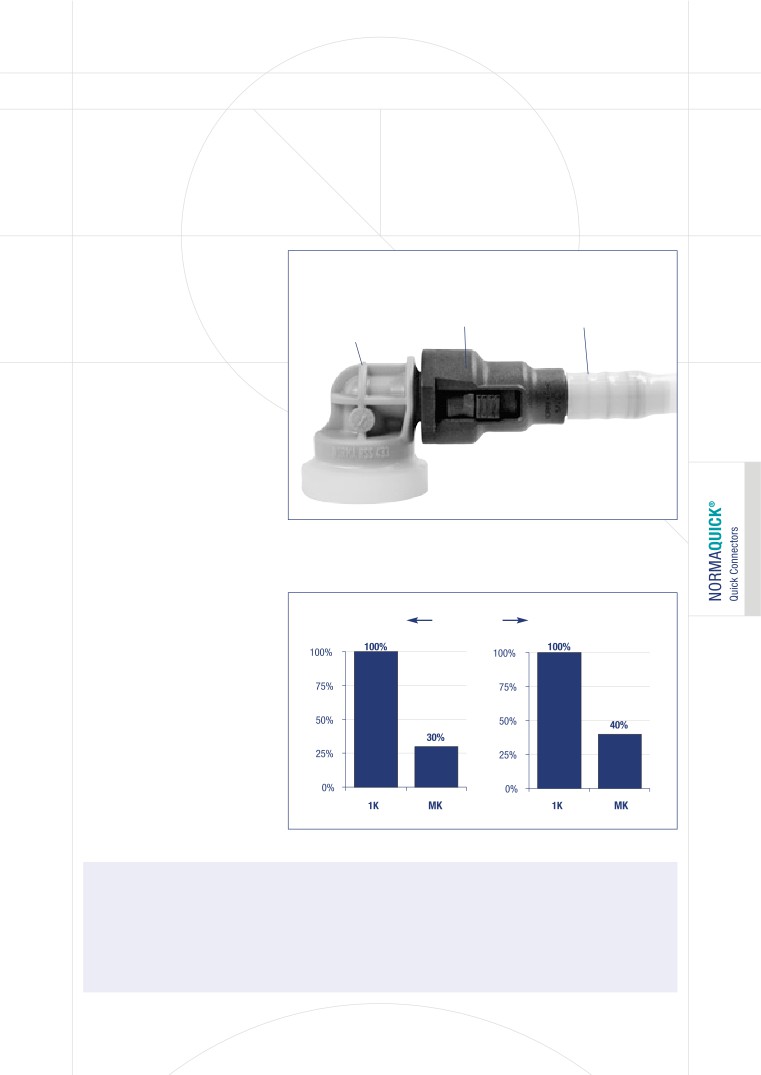

NORMAQUICK® MK with NORMAQUICK® S

• Firtree

NORMAQUICK® MK

NORMAQUICK® S

Optional O-ring

Multishot spigot

Quick connector

on firtree

Insiders’ Tip:

The perfectly matched system is achie-

ved when combining NORMAQUICK®

MK connecting spigots and NORMA-

FLEX® fluid systems.

Comparison of permeation rates Shed test to Carb Specification

Technical features

Phase II

Test fuel

TF 1

• Meeting the requirements of

ENG standard 016, VW TL 82417 and

KT-2KDL-0802

Reduced permeation achieved by means of MK connectors

The advantages at a glance

• Drastically reduced permeation rates at the connection between the plastic fuel tank and the fuel lines by means

of a 2-component material mixture

• Very good physical and chemical properties

131

NORMAQUICK® - Quick Connectors

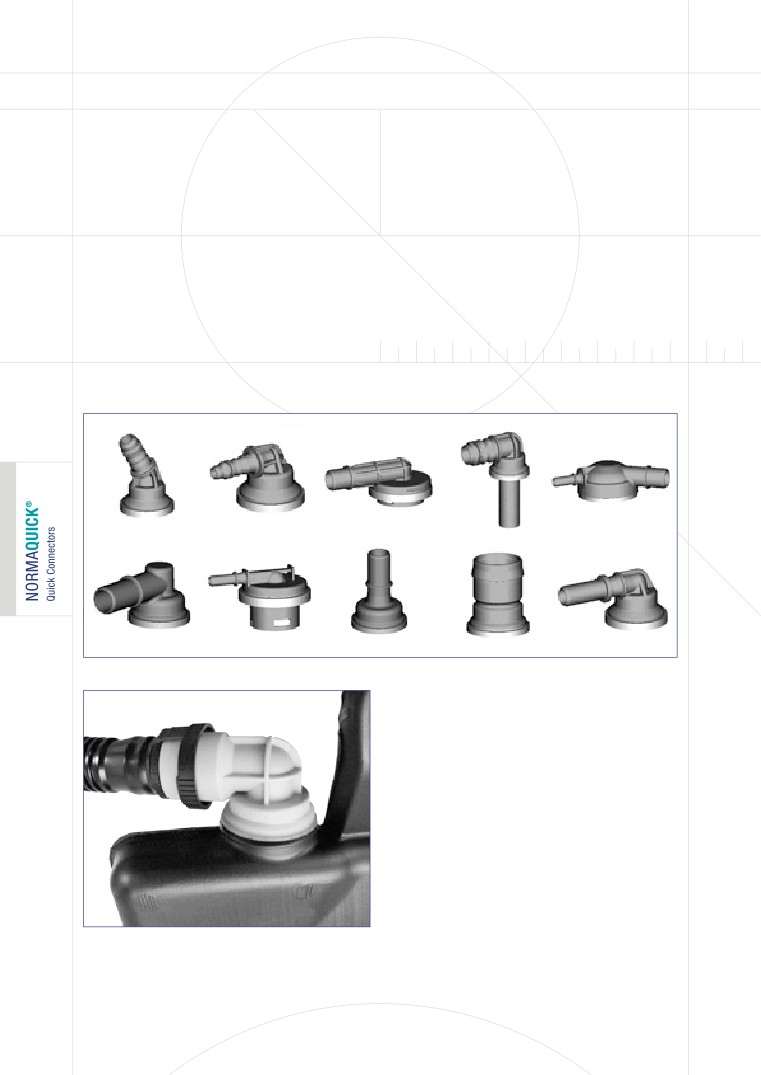

Survey of sizes

The NORMAQUICK® MK is not a standard part. All projects are

NORMAQUICK®

MK

based on special customer requirements. We shall therefore be

pleased to receive a precise description of your application in

order to be able to offer you an optimal,

customised solution.

Applications

• Fuel tank ventilation systems

• Fuel tank filler systems

Connector types

TB

TB

TB

SAE

SAE

SAE

SAE

V2

SAE

SAE

SAE

TB: Firtree

V2: NORMAQUICK® V2

SAE: Connecting spigot to SAE

NORMAQUICK® MK

132